In the same section

Civil Engineering Laboratory

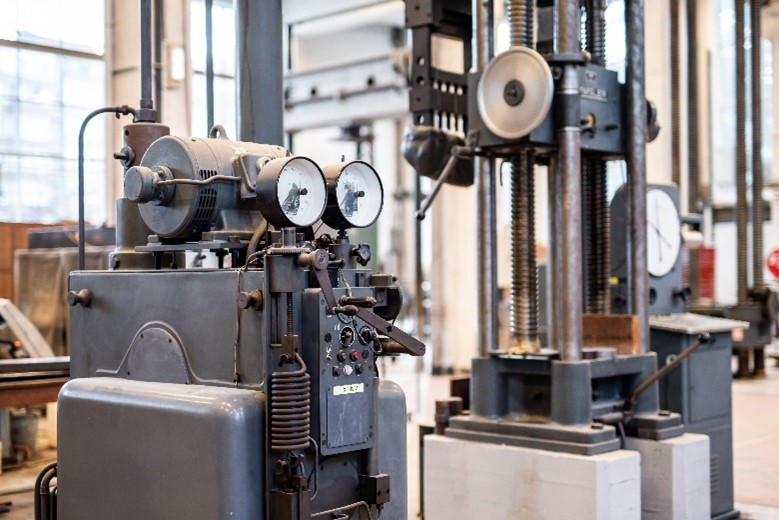

BATir-LGC was created in 1981 to foster experimental research on civil engineering materials and structures. Capitalizing on the availability of large testing facilities and a longstanding collaboration with the Research Centre of the Cement Industry (CRIC-OCCN) hosted by ULB, a strong expertise has been developed in the field of testing, instrumentation and analysis in civil engineering cement-based materials, construction materials and concrete structures, in the lab or in situ.

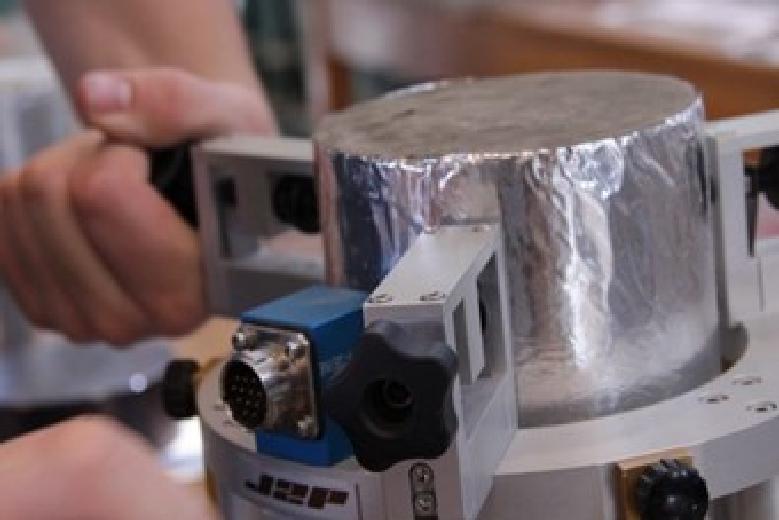

The Civil Engineering Laboratory (LGC) has large testing facilities (1700 square meters) with up-to-date loading or and testing equipment and data acquisition systems. The laboratory is able to conduct static, long-term sustained and fatigue loading on specimens or structural elements and is equipped with state-of-the-art non-destructive testing and material characterization equipment. These include compressive and tensile rig tests, extensometers, slab testing, calorimeters, Eirich concrete mixers, corrugated tube testing, ring tests, temperature stress testing machine, next to other characterization equipment and temperature, RH and capillary pore pressure sensors, etc. The laboratory has a wide range of hydraulic cylinders equipped with load measuring cells. Climatic chambers and ovens next to acoustic emission and ultrasonic measurement equipment are present.

Research lines

The LGC comprises the groups of:

- Prof. Arnaud DERAEMAEKER (structural health monitoring) ;

- Prof. Didier SNOECK (sustainable structural design) ;

- Prof. Stéphanie STAQUET (early-age behaviour of cement-based systems).

Structural health monitoring – Arnaud DERAEMAEKER

The research activities in the field of structural health monitoring aim at developing automated and robust systems capable of detecting the early onset of damage. In addition to helping to avoid catastrophic accidents, these novel technologies can also help drastically reduce the cost of maintenance and increase the serviceability as well as the service life of the aging infrastructure. After having developed for several years ambient-vibration-based monitoring systems, the team is currently focusing on ultrasonic techniques using embedded piezoelectric transducers. The research deals with all elements in the chain of the monitoring systems, from the design and fabrication of the transducers, to the data processing, feature extraction, and setting of threshold for automated alarms. Special attention is paid to the filtering of the environmental effects in order to avoid false alarms.

Sustainable structural design – Didier SNOECK

In the group of sustainable structural design a bridge is built between the two near worlds of concrete technology and structural concrete, in order to improve the durability and sustainability. The main topics are new concrete compositions (use of supplementary cementitious materials, alkali-activated binders, alternative binder systems and geomaterials, sulphur concrete,…), the circular use of construction materials, novel admixtures, the use of reinforcing materials (fibres and fabrics) to have structural retrofitting, new industrialized construction techniques and thermal comfort using phase-change materials in concrete structures. Furthermore, a link is made with the improvement of durability and self-healing of cementitious materials, and to build civil infrastructures which are stronger, more durable and which last for future generations.

Construction materials engineering – Stéphanie STAQUET

The research group construction materials engineering has the objective of developing strategies to prevent the risk of cracking of concrete by restraint shrinkage occurring usually at the early stages of the hardening of the concrete compositions. It includes the development of experimental techniques for the monitoring of the setting, the shrinkage in free and restraint conditions, the elastic properties, the creep and relaxation in tension and in compression at multiple scales. It includes also the development of new concretes composed by alkali-activated binders, recycled aggregates, municipal solid waste incinerator fly ashes, limestone filler for example which are investigated to valorize local materials available in Belgium for the construction sector.